DYE PENETRANT TESTING

DYE Penetrant Testing

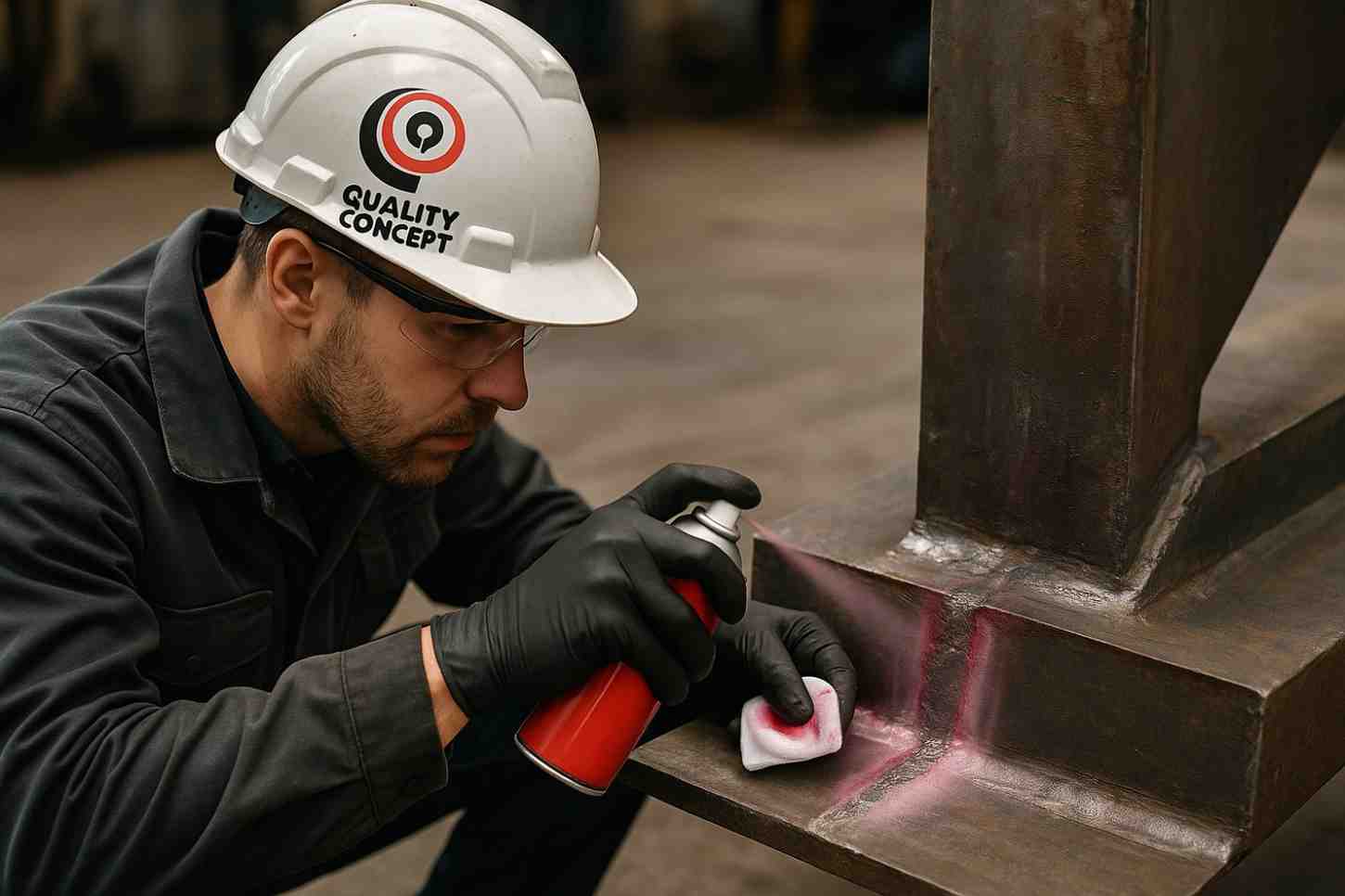

At QUALITY CONCEPT Welding Solution Private Limited, we offer reliable Dye Penetrant Testing (DPT) services to detect surface-breaking defects such as cracks, porosity, and laps in welds and metallic components. This non-destructive testing method uses visible or fluorescent dye to highlight imperfections that are not easily seen by the naked eye. Our certified inspectors ensure proper cleaning, application, and evaluation as per ASME, ASTM, and ISO standards.

- Customer Satisfaction 98%

- Utilization Works 85%

Dye Penetrant Testing (DPT) Services – Accurate Surface Defect Detection for Non-Porous Materials

Dye Penetrant Testing (DPT), also known as Liquid Penetrant Testing (LPT or PT), is a proven and cost-effective non-destructive testing (NDT) technique used to detect surface-breaking defects in non-porous materials. At Quality Concept Welding Solutions Pvt. Ltd., we provide high-quality DPT inspection services using visible or fluorescent dyes, enabling fast and accurate detection of critical surface flaws that may otherwise go unnoticed.

What is Dye Penetrant Testing?

DPT works by applying a specially formulated dye penetrant to the surface of the test piece. The dye seeps into any cracks or discontinuities, which are then revealed using a developer. This simple yet highly effective process helps identify cracks, porosity, laps, seams, leaks, and fatigue fractures in welds, castings, forgings, and machined parts. It is widely used for inspecting both ferrous and non-ferrous materials such as stainless steel, aluminum, copper, brass, and more.

Applications of Dye Penetrant Testing

- Weld Inspection: Detect surface cracks in fillet welds, butt joints, and heat-affected zones.

- Casting & Forging Evaluation: Identify surface shrinkage, porosity, or laps in non-ferrous components.

- Machined Surface Inspection: Check for grinding cracks, impact damage, or fatigue cracks.

- In-Service Equipment Testing: Ideal for condition monitoring of pressure parts and structural members.

- Leak Testing: Identify pinhole leaks in vessels, pipelines, and tanks.

Key Benefits of Dye Penetrant Testing

- Detects fine surface-breaking defects invisible to the naked eye

- Works on a wide range of materials, both ferrous and non-ferrous

- Low-cost and quick process for efficient inspections

- Highly portable, suitable for complex shapes and sizes

- Immediate on-site results with visual proof of defect location

Why Choose Quality Concept for DPT Services?

We ensure precise and reliable DPT testing by combining expert technicians with advanced methods:

- Experienced Technicians: All testing is conducted by ASNT Level II certified inspectors with in-depth field knowledge.

- Visible & Fluorescent Methods: Offering both visible red dye and fluorescent dye (UV light inspection) based on environment and sensitivity needs.

- On-Site & In-House Capability: Available for field inspections as well as shop-floor quality control.

- Standard Compliance: Procedures performed as per ASME Section V, ASTM E165, ISO 3452, AWS D1.1, and other industry standards.

- Eco-Friendly & Safe Chemicals: Use of low-toxicity, biodegradable penetrants and developers compliant with environmental safety norms.

Industries We Serve

- Pressure Vessel Manufacturing

- Oil & Gas Refineries

- Structural Steel Fabrication

- Aerospace Components

- Power Plants & Boilers

- Railway & Metro Fabrication

- Foundries and Forging Units

- Chemical & Pharmaceutical Equipment

Schedule Your Dye Penetrant Testing Today

For reliable and accurate surface defect detection, contact Quality Concept Welding Solutions Pvt. Ltd. or call +91-8377885000 / 8377885001 to discuss your DPT service requirements.